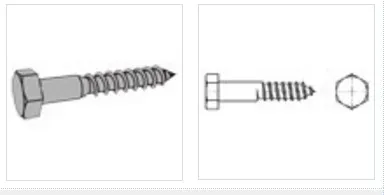

CNC Brass Fitting T-Joint and Ball Screw

CNC brass fitting t-joint and ball screwSpecification:1.MaterialStainless steel: SUS303, SUS304, SUS316, SUS316L, SUS430, SUS440, etcAluminum: 6061-T6, 6063-T5, 7075-T6,......

Send Inquiry

Product Description

CNC brass fitting t-joint and ball screw

Specification:

Technical Details

Material Used Table

Equipment :

Why Choose us:

1. Fully Machining Services:

Gringing parts , Machining parts, CNC milling and turning parts , CNC milling parts, CNC

metal parts, grinding parts, stamping parts, casting and forging parts, assembly service.

2.Various Machining Materials:

Metal parts, stainless steel parts, alloy steel parts ,brass parts, bronze parts, copper

parts, aluminum parts, plastic parts, ect.

3.Various Finishes:

Anodizing, Electroplating, Polishing, Powder Coating, Blacken, Hardening, Painting and

many other treatment of the parts.

4.Quality Assurance :

IPQC inspect each precision grinding parts during every processing step; 100% inspection before shipment by micrometer, height gauge, projector measuring machine, coordinate

measuring machine(CMM), ect. Any disqualification will be responsible by us.

5.Advantage:

1>.Non-standard/standard/OEM/ODM/customized service provided

2> No MOQ, no quantity limited

3 >Fast lead time

4> Can meet DIN,JIS,ASTM,AISI,BS,GB standard

Related Products

Equipment Show

After Service

Welcome consult with us, we service:

1. Best Solution for your production

2. Fast delivery for your urgent order.

Specification:

| 1.Material | Stainless steel: SUS303, SUS304, SUS316, SUS316L, SUS430, SUS440, etc Aluminum: 6061-T6, 6063-T5, 7075-T6, 2011, 2017, 2024, 5052, 5083, 6082 etc Brass: C11000, C10200, C12000, C26000, C36000, etc Carbon steel: 1010, 1015, 1020, 1025, 1030, 1035, 1040, 1045, etc Plastic:PVC, POM, Telfon, Delrin,PEEK,Nylon, ABS, PC, PP,PA6, PA66, etc Free cutting steel: 1211, 12L13, 12L14, 1215, etc Tool Steel: HSS M2,ASP23,H13,1.2344,D2,1.2379,etc |

2.Tolerance | +/-0.05mm |

| 3.Finishing | anodizing,polishing,plating ,blacken ect |

| 4.Edges and holes | debarred |

| 5.Surfaces | free of scratches |

| 6.Material capabilities | aluminum, stainless steel, copper, plastic and more |

| 7.Various materials and finishing ways are available | |

| 8.Non-standard aluminum product | |

| 9.Material and finishing comply with RoHS Directive | |

| 10.Small orders are welcome | |

Technical Details

Technical Process | CNC machining, EDM W/C |

Dimension | Client's artwork is available |

Capability | Milling:Length,machining range up to 1100*600 mm |

Turning: Diameter 0.05mm~300mm ; Length 0.5mm ~ 750mm | |

Wire Cutting: machining range can up to 450*400*300mm | |

Precision | Turning and Milling:+/- 0.002mm(+/-0.000098 inch) |

Wire Cutting: +/- 0.002 mm (+/-0.000098 inch) |

Material Used Table

| S/N | TYPE | CHINA | USA | JAPAN | GERMANY | SWEDEN |

| GB | ASTM | JIS | DIN | ASSAB | ||

| 1 | Martenslte stainless steel | 9CR 18Mov | 440c | sus440c | X105CrMo17 | 440CI |

| 2 | Martenslte stainless steel | / | / | / | / | S136H |

| 3 | Austensite stainless steel | 01Cr18N19 | 304 | SUS304 | X5Crnl 13-10 | / |

| 4 | Austensite stainless steel | Y1Cr18N19 | 303 | SUS303 | X12CrniS18.8 | / |

| 5 | Prehardened stainless steel | Cr12Mov | D2 | SKD11 | X165CrMov48 | XW-41 |

| 6 | Cold work die steel | 0Cr17nl4Cu4Nb | 17-4PH | SUS630 | X5CrNiCuNb | / |

| 7 | Cold work die steel | / | / | / | / | DF-2 |

| 8 | Powderhigh Speed Steel | / | / | / | / | ASO-23 |

| 9 | Powderhigh Speed Steel | / | CPM-10V | / | / | / |

| 10 | Cold work die steel | C6Mov | A2 | SKD12 | X100CrMov5 | / |

| 11 | Cold work die steel | 7Mn2CrMo | A6 | / | / | / |

| 12 | Carbon construction steel | 45 | 1045 | S45C | C45 | / |

| 13 | Spring Steel | 65 | 1065 | S65C | C65 | / |

| 14 | Spring Steel | / | 1095 | / | / | / |

Equipment :

| Name | Quantity (set) | Origin | Precision | Running Distance |

| CNC gantry machine | 1 | China | 0.005mm | 2000*1300mm |

| CNC machining Centers | 1 | China | 0.005mm | 600*500mm |

| CNC horizontal machine center | 4 | China | 0.005mm | 800*500mm |

| CNC machining Centers | 9 | China | 0.005mm | 600*500mm |

| CNC lathe/mill machine center | 4 | China | 0.005mm | 50*150mm |

| Lathe Machine | 2 | China | 0.01mm | 200*750mm |

| Milling Machine | 10 | China | 0.01mm | 300*700mm |

| grinding machine | 3 | Tai Wan | 0.003mm | 150*400mm |

| High Speed W/C | 4 | China | 0.015mm | 250*300*400mm |

| Slow Feeding W/C | 1 | China | ||

| Sand Blast Machine | 1 | China | ||

| Polishing Machine | 1 | China |

Why Choose us:

1. Fully Machining Services:

Gringing parts , Machining parts, CNC milling and turning parts , CNC milling parts, CNC

metal parts, grinding parts, stamping parts, casting and forging parts, assembly service.

2.Various Machining Materials:

Metal parts, stainless steel parts, alloy steel parts ,brass parts, bronze parts, copper

parts, aluminum parts, plastic parts, ect.

3.Various Finishes:

Anodizing, Electroplating, Polishing, Powder Coating, Blacken, Hardening, Painting and

many other treatment of the parts.

4.Quality Assurance :

IPQC inspect each precision grinding parts during every processing step; 100% inspection before shipment by micrometer, height gauge, projector measuring machine, coordinate

measuring machine(CMM), ect. Any disqualification will be responsible by us.

5.Advantage:

1>.Non-standard/standard/OEM/ODM/customized service provided

2> No MOQ, no quantity limited

3 >Fast lead time

4> Can meet DIN,JIS,ASTM,AISI,BS,GB standard

Related Products

Equipment Show

After Service

Welcome consult with us, we service:

1. Best Solution for your production

2. Fast delivery for your urgent order.

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.