Why Are Slotted Machine Screws Still Widely Used in Modern Applications?

2025-09-25

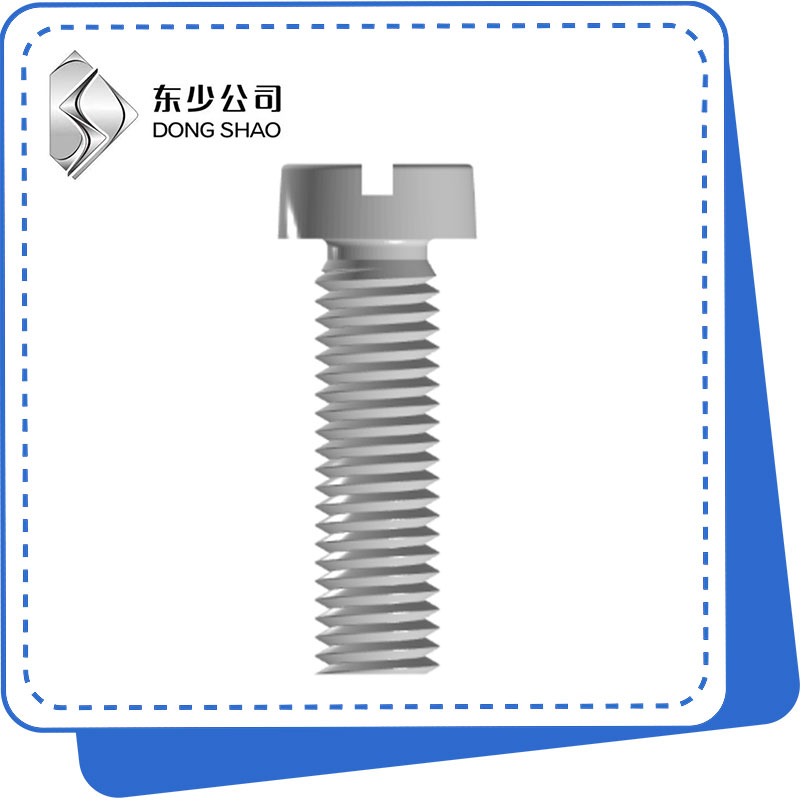

Slotted Machine Screws may appear to be a traditional fastener, yet they remain one of the most commonly used components across industrial, mechanical, and construction projects. With their simple design, reliable performance, and compatibility with standard tools, they continue to meet the needs of engineers, manufacturers, and maintenance specialists worldwide. As a professional supplier, Hebei Dongshao Fastener Manufacturing Co., Ltd. has specialized in producing high-quality Slotted Machine Screws, ensuring durability, precision, and compliance with international standards.

The Function of Slotted Machine Screws

The primary function of Slotted Machine Screws is to securely fasten metal parts together, often in machinery, equipment, and electrical applications. Their slot drive design allows for easy tightening and loosening with standard flat-blade screwdrivers. Unlike self-tapping screws, they require a pre-threaded hole or nut, providing a more stable and precise connection.

Main functions include:

-

Joining metal-to-metal components

-

Securing electrical devices and panels

-

Serving as replacement parts in repair and maintenance

-

Allowing controlled tightening and adjustment

The Effectiveness in Use

The use of Slotted Machine Screws brings clear benefits. Their simplicity reduces tool compatibility issues, while their wide availability ensures quick replacement. When properly installed, they provide long-term stability. At Hebei Dongshao Fastener Manufacturing Co., Ltd., each batch undergoes strict quality control, ensuring high tensile strength, resistance to stripping, and consistent threading.

Advantages in application:

-

Simple and versatile drive system

-

Suitable for multiple industrial and household applications

-

Cost-effective while maintaining quality

-

Easy to replace in maintenance tasks

Importance and Role in Industry

Despite the development of other drive types, Slotted Machine Screws remain essential due to their compatibility with universal tools. They are especially useful in environments where specialized drivers are unavailable. Moreover, their structure makes them suitable for delicate or low-torque applications, such as electronics and small machinery.

Sample Specification Table

| Parameter | Description |

|---|---|

| Material | Carbon Steel, Stainless Steel |

| Surface Treatment | Zinc Plated, Nickel, Black Oxide |

| Sizes Available | M2 – M12 |

| Standard Compliance | DIN, ANSI, ISO |

| Application Fields | Machinery, Electronics, Hardware |

Q&A Section with First-Person Perspective

Q1: Why should I consider Slotted Machine Screws for my project?

A1: I prefer Slotted Machine Screws because they are versatile, easy to install, and readily available in various sizes. Their universal slot design means I don't need special tools, which saves time and cost.

Q2: Are Slotted Machine Screws reliable for long-term industrial use?

A2: I have tested them in multiple scenarios, and the results are consistent. The screws manufactured by Hebei Dongshao Fastener Manufacturing Co., Ltd. maintain durability under repeated tightening and resist wear, making them suitable for long-term use.

Q3: How can I choose the right Slotted Machine Screws for my equipment?

A3: I usually check the material, coating, and standard compliance before selecting. Stainless steel offers corrosion resistance, while zinc plating provides a clean appearance. Choosing from a trusted manufacturer like Hebei Dongshao Fastener Manufacturing Co., Ltd. ensures both precision and safety.

Conclusion

Slotted Machine Screws may be simple, but their importance across industries cannot be underestimated. They are versatile, effective, and cost-efficient, making them a valuable choice for engineers and technicians. Whether for large-scale manufacturing or individual repair, Hebei Dongshao Fastener Manufacturing Co., Ltd. delivers screws that meet international quality standards while maintaining competitive prices.

If you are looking for durable and reliable fastening solutions, don't hesitate to contact us today.