What Makes CNC Machining Mold Blocks Essential for Precision Manufacturing?

2025-12-04

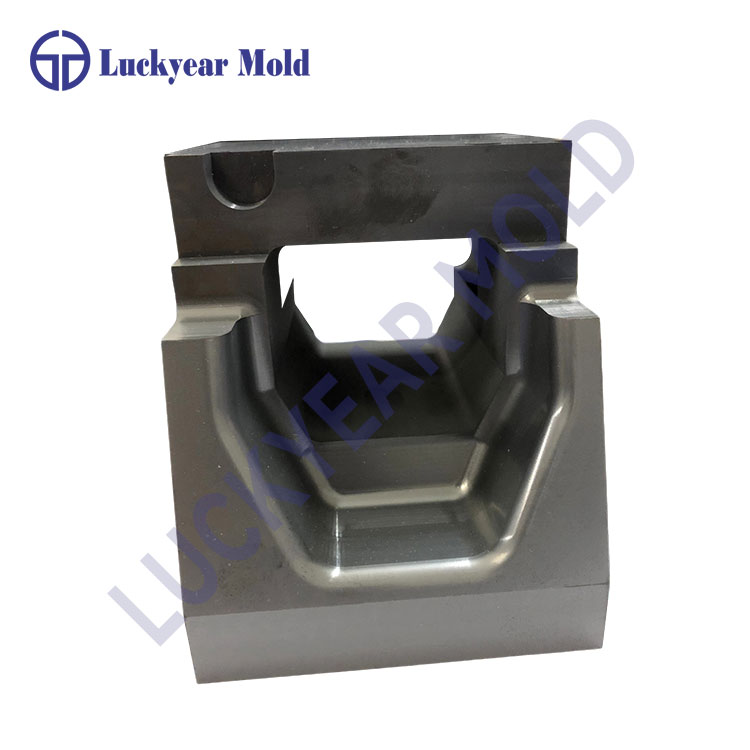

As modern manufacturing continues to demand higher accuracy and faster production cycles, CNC Machining Mold Blocks have become a core element for industrial tooling. These components, produced with advanced multi-axis machining, ensure stable performance, long service life, and consistent dimensional accuracy. At Dongguan Luckyear Precision Mold Parts Co., Ltd., we specialize in designing and manufacturing premium mold blocks that meet global market requirements. In my daily work, I often rely on CNC Machining Mold Blocks to achieve precise molding performance for clients across various industries.

Understanding CNC Machining Mold Blocks

CNC machining mold blocks are solid metal blocks processed through computer-controlled cutting systems. They are widely used in injection molds, die-casting molds, stamping molds, and automation fixtures.

Key functions

-

Maintain mold structure and ensure dimensional consistency

-

Provide stable thermal and mechanical performance

-

Improve the precision and lifespan of mold components

-

Adapt to high-strength, high-temperature production environments

Main applications

-

Automotive components

-

Electronic housings

-

Medical equipment parts

-

Industrial machinery

Why Are CNC Machining Mold Blocks So Important?

Their importance lies in precision, stability, and efficiency. When I design a mold system, I prefer CNC-machined blocks because they significantly reduce machining errors and assembly deviations. This brings stronger productivity and more reliable mold operation.

Performance advantages

| Feature | Description |

|---|---|

| Accuracy | ±0.005 mm controlling tolerance |

| Material Options | P20, NAK80, H13, S136, 1.2343, customized steels |

| Surface Finish | Ra 0.4–1.2 μm |

| Machining Methods | Milling, grinding, EDM, wire cutting |

| Customization | 2D/3D drawing support |

Q&A: Common Questions About CNC Machining Mold Blocks

1. What problem do CNC Machining Mold Blocks solve for me?

They eliminate dimensional instability and shorten production time, ensuring reliable mold structure.

2. Why should I choose high-precision mold blocks from Dongguan Luckyear Precision Mold Parts Co., Ltd.?

Because our machining accuracy, material selection, and QC process ensure stable performance and long service life.

3. How do CNC Machining Mold Blocks improve my manufacturing results?

They enhance mold durability, reduce rework costs, and ensure uniform molding quality in mass production.

Effects and Benefits in Real Production

When used in injection molding or metal-forming systems, CNC Machining Mold Blocks deliver measurable performance:

-

Superior dimensional control reduces part-to-part variation

-

Enhanced mold stability extends mold service cycle

-

Better heat balance improves surface finish of molded parts

-

Lower maintenance frequency saves long-term costs

I have repeatedly seen customers improve yield rate by 15%–30% simply by upgrading to our precision-machined mold blocks.

Why Choose Dongguan Luckyear Precision Mold Parts Co., Ltd.?

We combine advanced machining equipment, strict quality management, and rich engineering experience.

Our strengths

-

High-precision multi-axis CNC machining

-

Comprehensive material options and heat treatment support

-

In-house grinding, EDM, and WEDM capabilities

-

Fast delivery with stable mass-production capacity

-

Full technical support from drawing to finished product

Conclusion

In today's competitive manufacturing environment, CNC Machining Mold Blocks are indispensable for achieving stability, precision, and efficiency. Whether you are upgrading molds, optimizing production, or developing new tooling solutions, Dongguan Luckyear Precision Mold Parts Co., Ltd. is ready to support your project with high-quality customized solutions.

If you want reliable, long-lasting, and precision-engineered mold blocks, don't hesitate to contact us for professional service and competitive pricing.