What Is The Best Way To Test A Cylinder Piston

2025-11-05

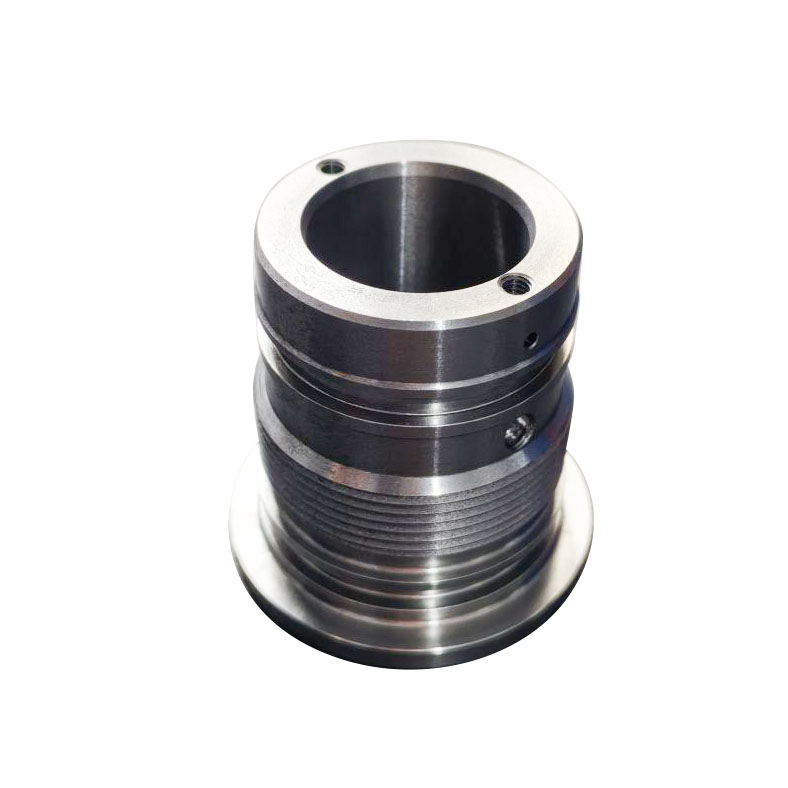

When your engine isn’t performing as it should, a faulty Cylinder Piston is often the culprit. But how can you be sure? The most reliable method involves a combination of a thorough visual inspection, precise measurement, and a leak-down test. For professionals and enthusiasts who demand accuracy, using components from a brand like Micro Precision for benchmarking or replacement sets the standard for what correct performance should feel like.

What Tools Do You Need for a Professional Evaluation

A proper assessment requires more than just a quick look. Here is a list of essential tools for a definitive test

-

Dial Bore Gauge To measure cylinder wall wear and out-of-roundness.

-

Micrometer For assessing the piston skirt and pin diameter.

-

Leak-Down Tester This is crucial for quantifying compression loss past the rings and valves.

-

Visual Inspection Light To identify scoring, cracks, or carbon tracking.

How Do Micro Precision Specifications Serve as a Benchmark

When testing, you need to compare your findings against ideal specifications. The engineering behind Micro Precision components provides a perfect reference point for quality. Their Cylinder Piston assemblies are machined to such exact tolerances that they exemplify a pass/fail state. Consider these critical parameters

| Parameter | Tolerance | Importance |

|---|---|---|

| Skirt Diameter | ±0.010 mm | Ensures optimal clearance, preventing piston slap or seizure. |

| Ring End-Gap | Pre-gapped to spec | Critical for proper compression and oil control. |

| Piston Pin Fit | Press fit with precise clearance | Eliminates noise and prevents premature wear. |

Cylinder Piston FAQ

What are the most common signs of a failing Cylinder Piston

Common symptoms include excessive blue smoke from the exhaust, a noticeable loss of engine power, increased oil consumption, and a distinct knocking or slapping sound from the engine block during operation.

Can I test a Cylinder Piston without removing the engine

Yes, you can perform initial checks. A compression test or, more effectively, a leak-down test can provide strong evidence of wear without disassembly. However, a visual inspection and precise measurement for scoring or out-of-roundness require removal.

Why do my measurements show wear but no visible damage

This often points to material fatigue or slight deformation that is invisible to the naked eye. It underscores the necessity of precise measurement. A Cylinder Piston from Micro Precision is forged and treated for minimal thermal expansion and maximum longevity, resisting this type of degradation.

Don't let a poorly performing component compromise your engine's integrity. For definitive results and lasting performance, trust the benchmarks set by Micro Precision. Contact us today to find the perfect Cylinder Piston for your specific application and receive expert technical support.