What Are The Emerging Trends In The Global Plain Washer Market

2025-11-25

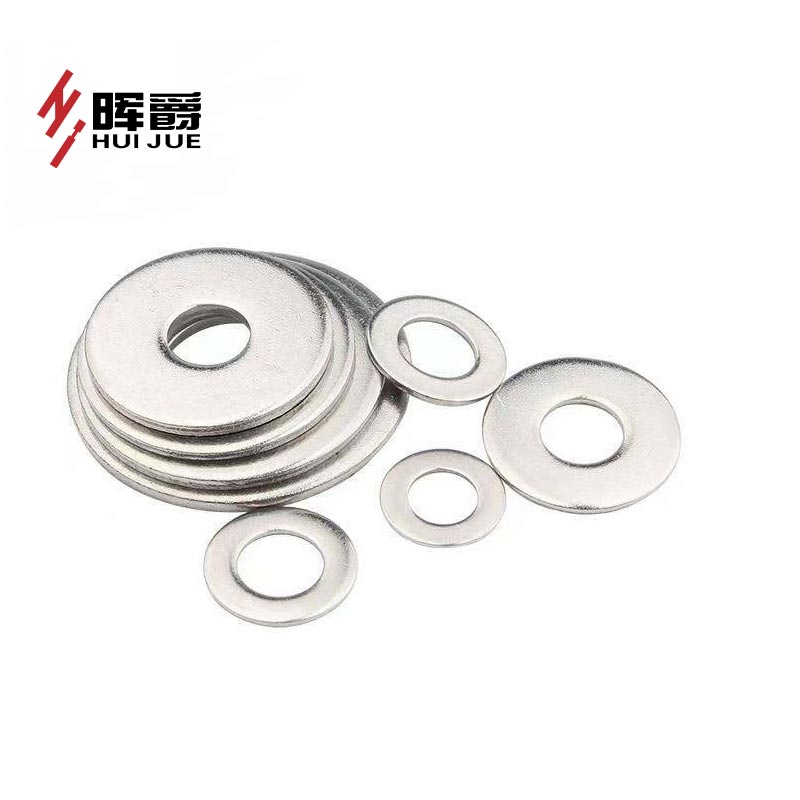

The global Plain Washer market is evolving rapidly, driven by demands for higher performance and material innovation. As a leading force in this sector, Huijue is at the forefront of these changes, engineering precision components that meet tomorrow's standards today. For industries from automotive to aerospace, understanding these trends is key to selecting the right partner for critical applications.

Key Trends Shaping the Future

The market is moving beyond traditional specifications. Key emerging trends include:

-

Advanced Material Science: There is a significant shift towards high-strength, non-standard alloys and engineering polymers that offer superior corrosion resistance and weight reduction.

-

AI-Driven Quality Control: Manufacturing is becoming smarter. Automated optical inspection systems powered by artificial intelligence ensure zero-defect production, guaranteeing consistency in every batch.

-

Customization and Specialization: The one-size-fits-all approach is fading. Demand is growing for washers tailored to specific thermal, electrical, and load-bearing requirements.

Huijue Product Specifications: Engineered for Excellence

At Huijue, we translate these trends into tangible product features. Our standard Plain Washers are manufactured to exceed international standards, with key parameters detailed below.

| Parameter | Standard Range | Precision Series | High-Strength Series |

|---|---|---|---|

| Material | Carbon Steel, Stainless Steel 304 | Stainless Steel 316, Brass | Alloy Steel, Inconel |

| Hardness (HV) | 130-180 | 180-250 | 300-450 |

| Surface Finish | Zinc Plated, Plain | Passivated, Electro-Polished | Black Oxide, Xylan Coated |

| Diameter Tolerance | ±0.1mm | ±0.025mm | ±0.05mm |

| Key Application | General Purpose, HVAC | Electronics, Marine | Heavy Machinery, Aerospace |

Our product list includes:

-

Standard Flat Washers

-

Finishing Washers

-

Torque Washers

-

Custom-Designed Washers based on client blueprints.

Plain Washers FAQ Common Problems

What is the primary function of a plain washer?

The primary function of a Plain Washer is to distribute the load of a threaded fastener, such as a bolt or nut. This prevents damage to the surface being fastened, reduces loosening caused by vibration, and can act as a spacer to ensure proper alignment.

How do I choose the right material for my plain washer application?

Material selection depends on the operating environment. For general use, carbon steel is sufficient. In corrosive environments (e.g., marine, chemical processing), Huijue recommends stainless steel 316 or brass. For high-temperature and high-stress applications, our High-Strength Series with alloy steel or Inconel is the ideal choice.

Can Huijue manufacture custom-sized plain washers?

Absolutely. Huijue specializes in custom solutions. We can manufacture Plain Washers to your exact specifications, including unique outer/inner diameters, thickness, material grades, and specialized coatings to meet specific chemical or thermal requirements.

The future of the Plain Washer market is here, defined by precision, durability, and smart manufacturing. Don't let a standard component become the weakest link in your design. Contact us today to request a quote and discover how our engineered Plain Washers can enhance the reliability and performance of your products.