What Are the Differences Between Plain Washers and Spring Washers

2025-12-09

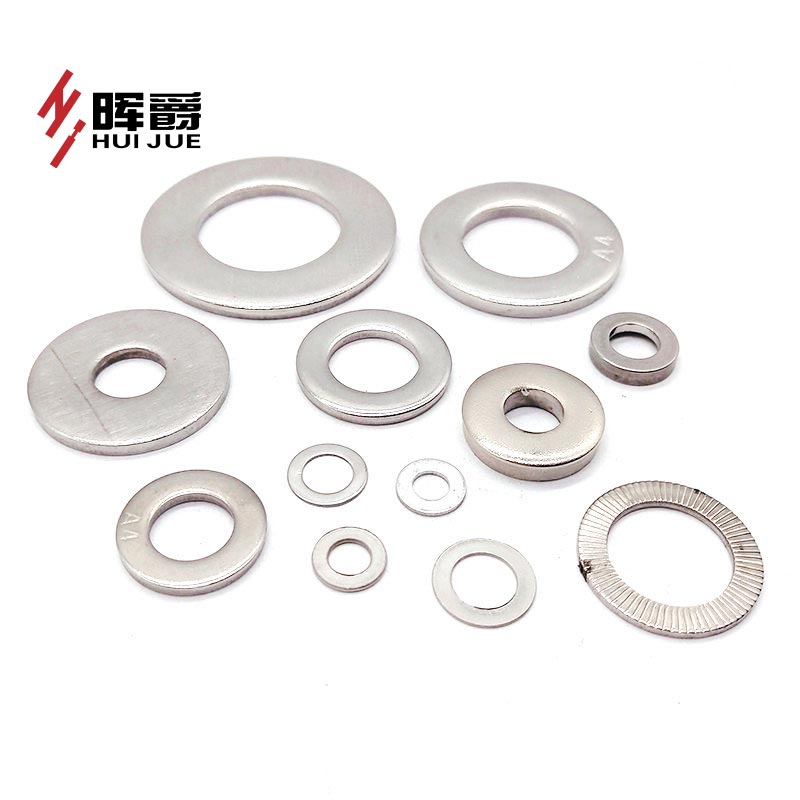

When selecting hardware for an assembly, choosing the right washer is crucial for performance and longevity. While both Plain Washers and Spring Washers fall under the broad category of washers, their functions are distinctly different. At Huijue, we specialize in manufacturing precision-engineered washers, and understanding this difference is key to ensuring the integrity of your projects. This guide will break down their unique roles, applications, and how Huijue's product specifications ensure optimal results.

Core Function: Load Distribution vs. Tension Maintenance

The fundamental difference lies in their primary purpose:

-

Plain Washers (Flat Washers): Their main role is to distribute the load of a fastener's head or nut. This prevents damage to the surface, reduces friction during tightening, and can act as a spacer.

-

Spring Washers (Lock Washers): Their primary function is to prevent loosening due to vibration or thermal expansion. They provide a continuous spring force that maintains tension in the bolted joint.

Huijue Product Specification Comparison

The following table outlines key parameters for standard Huijue offerings, highlighting their design divergence:

| Feature | Huijue Plain Washers | Huijue Spring Washers |

|---|---|---|

| Primary Function | Load Distribution, Surface Protection | Vibration Resistance, Locking |

| Typical Design | Flat, solid ring with uniform thickness. | Helical (split) or curved design to create spring action. |

| Key Material (Huijue Standard) | Carbon Steel, Stainless Steel (A2/A4), Brass | Carbon Steel (Spring Steel), Stainless Steel (A2/A4) |

| Load Handling | Distributes compressive load over a wider area. | Applies axial spring force to maintain clamp load. |

| Best Used For | Protecting soft surfaces, covering large holes, spacing. | Applications with high vibration or dynamic loads. |

Huijue Plain Washers are available in a wide range of standard and metric sizes, with precise inner/outer diameter and thickness tolerances. Our Spring Washers, particularly our helical lock washers, are heat-treated to provide consistent and reliable elastic force.

Plain Washers FAQ

Q: Can I use a plain washer as a lock washer?

A: No. A Plain Washer is not designed for locking. It lacks the spring action needed to maintain tension under vibration. Using it as a lock washer can lead to joint failure. For locking, always pair a Spring Washer with a Plain Washer or use a dedicated locking fastener.

Q: How do I choose the correct size for a plain washer?

A: The correct Plain Washer size depends on the fastener. The inner diameter should be slightly larger than the bolt's shank diameter, while the outer diameter should be large enough to adequately distribute the load without interfering with the assembly. Refer to Huijue's detailed sizing charts for precise matching.

Q: Are Huijue plain washers corrosion-resistant?

A: Huijue offers Plain Washers in various materials. Our standard carbon steel washers provide basic protection, while our A2 (304) and A4 (316) Stainless Steel Plain Washers offer excellent corrosion resistance for harsh environments like marine or chemical applications.

Choosing the Right Washer for Your Application

Selecting between a plain and spring washer is not a matter of preference but of engineering requirement. Use Huijue Plain Washers when you need to protect surfaces, distribute pressure, or act as a spacer. Opt for Huijue Spring Washers when the primary threat is vibration-induced loosening. For maximum security in critical applications, they are often used together: the Plain Washer protects the surface and distributes the load, while the Spring Washer sits underneath the nut to keep it locked tight.

Contact Us today for expert guidance! Whether you need a standard Plain Washer or a high-performance Spring Washer, Huijue provides the quality, precision, and technical support you need. Visit our website or reach out to our engineering team to discuss your specifications and request a quote.