What Are the Common Failure Modes in Steel High Pressure Flanges and How to Prevent Them

2025-12-29

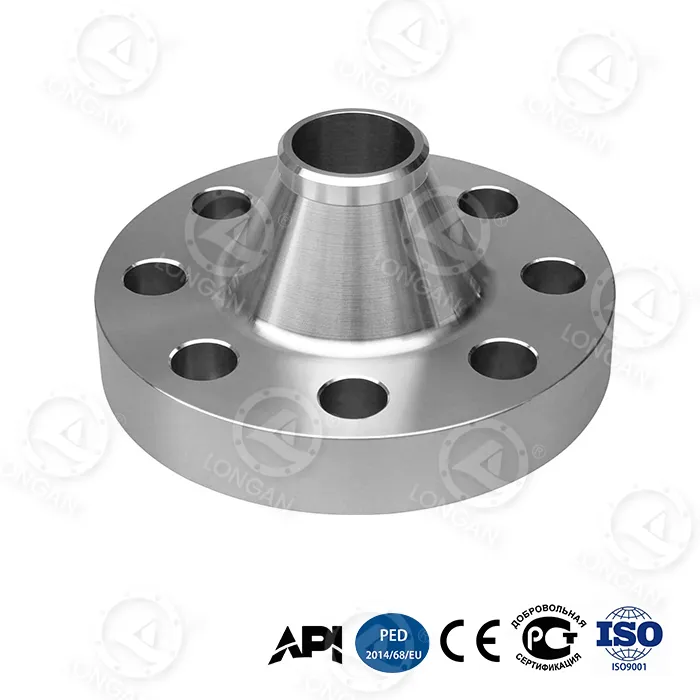

In high-pressure piping systems, the integrity of Steel High Pressure Flange connections is paramount. Failures can lead to catastrophic downtime, safety hazards, and significant financial loss. Understanding these failure modes and implementing proactive prevention strategies is a cornerstone of reliable operations. At Longan, we combine engineering expertise with premium manufacturing to help our clients mitigate these critical risks through superior products and knowledge.

The most prevalent failure modes for Steel High Pressure Flanges typically stem from improper selection, installation, or service conditions. Here are the key issues and how to address them:

Common Failure Modes & Prevention Checklist

-

Gasket Failure & Leakage: Caused by incorrect gasket material, insufficient bolt torque, or flange face damage.

-

Prevention: Precisely match gasket type to service (temperature, media). Follow controlled bolt tightening procedures (e.g., cross-torquing). Inspect flange sealing surfaces for scratches or warping.

-

-

Bolt Fatigue/Stress Corrosion Cracking: Bolts loosen under cyclic loads or crack in corrosive environments.

-

Prevention: Use correct bolt material grade (e.g., B7, L7). Employ proper lubrication and torque-to-yield methods. Consider environmental coatings or materials.

-

-

Flange Face Erosion/Corrosion: The sealing surface degrades from abrasive or corrosive flow.

-

Prevention: Specify appropriate material grades (e.g., Longan's F304/F316 stainless or ASTM A105 with coatings). Implement regular inspection schedules.

-

-

Warping/Distortion: Excessive bending loads or thermal shock can deform the flange.

-

Prevention: Ensure proper system support to avoid undue load transfer. Specify flanges with adequate rigidity for the service.

-

The table below summarizes the root causes and primary prevention focus for each mode:

| Failure Mode | Primary Root Cause | Key Prevention Focus |

|---|---|---|

| Gasket Leakage | Improper Installation/Selection | Controlled Bolt Torquing & Gasket Specification |

| Bolt Failure | Cyclic Stress / Corrosion | Bolt Material Grade & Tightening Procedure |

| Flange Face Damage | Material Incompatibility | Corrosion-Resistant Materials & Coatings |

Steel High Pressure Flange FAQ

Q: How often should flange bolt connections be re-torqued?

A: There is no universal schedule. Critical connections should be checked at initial startup after the first temperature cycle (hot re-torque). Subsequently, inspections should be based on system conditions, vibration levels, and temperature cycles, typically during planned maintenance shutdowns. A Longan technical advisor can help establish a condition-based program.

Q: Can a standard ASTM A105 carbon steel flange be used for highly corrosive service?

A: Generally, no. While A105 offers high strength, its corrosion resistance is limited. For corrosive media, materials like ASTM A182 F316 stainless steel or cladded flanges are necessary. Longan provides comprehensive material consulting to ensure compatibility with your process media.

Q: What is the significance of a Ring Type Joint (RTJ) flange in high-pressure service?

A: RTJ flanges use a metal ring gasket that sits in a machined groove, creating a robust, metal-to-metal seal. They are preferred for very high-pressure (Class 600 and above) or high-temperature applications because the seal becomes tighter as internal pressure increases, offering superior leak integrity compared to raised-face flanges in extreme conditions.

Proactive failure prevention begins with choosing a partner dedicated to quality and support. Longan manufactures Steel High Pressure Flanges to the most stringent international standards, ensuring dimensional accuracy, material traceability, and performance reliability. Our technical team is ready to assist you in selecting the optimal flange specification and implementing best-practice installation guidelines.

Contact us today for a detailed consultation or to request a quote for your next project. Let Longan be your reliable partner in ensuring system safety and uptime.