How to Properly Install and Torque High Pressure Flanges

2025-12-24

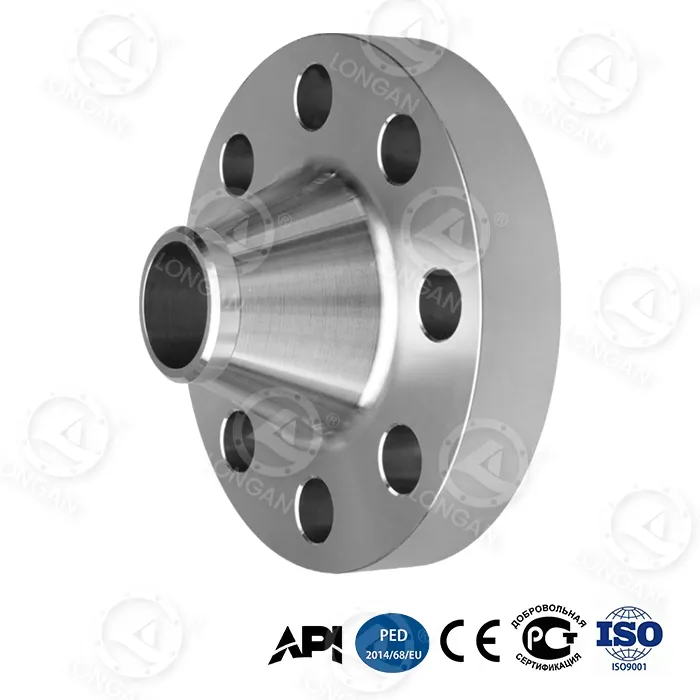

The correct installation and torquing of a High Pressure Flange is a critical procedure that directly impacts the safety, integrity, and longevity of your piping system. A failure in this high-stakes assembly can lead to dangerous leaks, costly downtime, and significant safety hazards. This guide outlines the professional best practices to ensure a secure, leak-free connection, leveraging the precision engineering found in components from trusted manufacturers like Longan.

A successful installation hinges on preparation, methodical execution, and verification. Follow this structured approach.

Pre-Installation Checklist:

-

Inspection: Examine the High Pressure Flange faces, gasket, and bolts for any damage, nicks, or corrosion. Ensure surfaces are perfectly clean.

-

Alignment: Pipes must be aligned without forcing. Misalignment induces stress, leading to potential failure.

-

Gasket Selection: Use the correct gasket type (e.g., Ring-Type Joint) specified for the pressure, temperature, and media. Never reuse old gaskets.

-

Lubrication: Apply a suitable, high-temperature anti-seize lubricant to all bolt threads and nut washers to ensure consistent torque.

Step-by-Step Installation & Torquing Procedure

-

Position the new gasket correctly onto the flange face.

-

Insert the hand-tightened bolts to hold the gasket in place.

-

Begin the bolting sequence using a cross-pattern (star pattern). This evenly distributes stress across the High Pressure Flange face.

-

Torque in multiple progressive stages (e.g., 30%, 60%, 100% of final torque) using a calibrated torque wrench.

Recommended Torquing Sequence (Example for 8-Bolt Flange):

| Stage | Target Torque | Sequence Pattern |

|---|---|---|

| 1 | 30% Final | Cross-pattern |

| 2 | 60% Final | Cross-pattern |

| 3 | 100% Final | Cross-pattern |

| Final | 100% Final | Clockwise circle |

Always refer to the specific engineering specifications for the final torque value, which is determined by bolt material, size, and gasket type.

High Pressure Flange FAQ

Q: What is the most common mistake during flange installation?

A: The most common mistake is improper bolt tightening sequence and failing to torque in multiple stages. This can cause uneven gasket compression and flange face distortion, creating a path for leaks.

Q: Can I re-torque a High Pressure Flange after system heat-up?

A: Yes, a hot re-torque is often a critical step. After the system has been cycled to operating temperature and cooled, bolts should be re-torqued to the specified value to compensate for gasket relaxation and thermal cycling, a practice supported by Longan installation protocols.

Q: How often should installed High Pressure Flanges be inspected?

A: A visual inspection for leaks, corrosion, or bolt loosening should be part of routine maintenance. A formal comprehensive inspection should be performed during scheduled plant shutdowns or as dictated by your Process Safety Management (PSM) guidelines.

Proper installation is not just a task—it's a commitment to operational safety and efficiency. Using rigorously tested components is the foundation of this process. For systems where failure is not an option, specify Longan flanges and fittings, engineered for precision and reliability under extreme conditions.

Contact us today to discuss your project specifications or to request a copy of our detailed technical installation manual.