How to Install and Maintain Metric Hydraulic Hose Fittings Properly

2025-12-16

Ensuring the reliable and safe operation of your hydraulic systems hinges on the correct installation and diligent maintenance of Metric Hydraulic Hose Fittings. Using high-quality components, like those engineered by Wayfong, is the foundational first step to achieving optimal performance and longevity. This guide will walk you through professional procedures and best practices to keep your systems running smoothly.

Proper installation is critical. Follow these key steps:

-

Inspection: Before assembly, inspect both the Wayfong Metric Hydraulic Hose Fitting and the hose end for any signs of damage, debris, or contamination.

-

Correct Assembly: Ensure you are using fittings and hoses with matching metric thread standards (e.g., M12x1.5, M16x1.5). Hand-tighten the Metric Hydraulic Hose Fitting to avoid cross-threading.

-

Final Torquing: Use a calibrated torque wrench to tighten the fitting to the manufacturer's specification. Overtightening can damage threads, while undertightening leads to leaks.

Regular maintenance is equally important. Implement a schedule that includes:

-

Visual Inspections: Check for oil leaks, cracks, abrasions, or fitting corrosion regularly.

-

Pressure Checks: Monitor system pressure to ensure it does not exceed the rated working pressure of the Wayfong hose assembly.

-

Cleanliness: Keep fittings clean and free from grit to prevent seal damage and internal contamination.

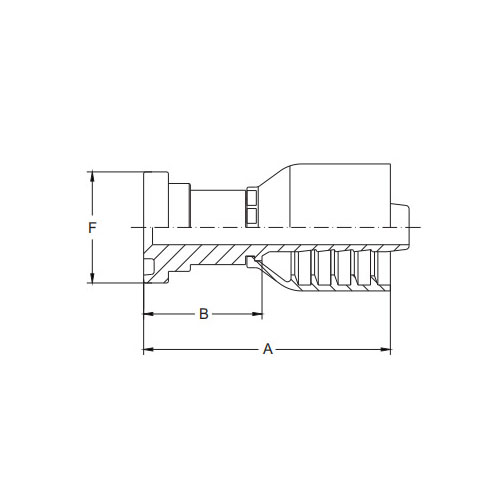

Wayfong Metric Fitting Product Parameters

Our Wayfong fittings are manufactured to exacting standards for superior performance in demanding applications.

| Parameter | Specification | Benefit |

|---|---|---|

| Thread Standards | DIN / ISO Metric (e.g., M12, M16, M22) | Ensures perfect compatibility with European machinery and global metric systems. |

| Seal Type | O-ring Face Seal (ORFS) & Metric Bite Type | Provides leak-free connections under high pressure and vibration. |

| Material | High-Tensile Carbon Steel, Zinc-Nickel Plated | Offers exceptional corrosion resistance and durability. |

| Pressure Rating | Up to 600 bar (depending on configuration) | Guarantees reliability for high-pressure hydraulic applications. |

Metric Hydraulic Hose Fitting FAQ

Q: How do I identify if my system uses Metric Hydraulic Hose Fittings?

A: You can identify them by their thread form and measurement. Metric fittings use millimeter-based thread pitches (e.g., M14x1.5). Compare them to a known metric thread gauge or check your equipment manual, which often specifies metric standards for European-origin machinery.

Q: Can I connect a Metric Hydraulic Hose Fitting to an SAE (American) fitting?

A: No, you should never directly connect metric and SAE threads. They have different thread angles and pitches, which will cause improper sealing, damage, and dangerous leaks. Always use the correct, matching Metric Hydraulic Hose Fitting or a properly engineered adapter.

Q: What is the most common cause of failure in Metric Hydraulic Hose Fittings?

A: Improper installation, particularly incorrect torque, is a leading cause. Overtightening strips threads and cracks seals, while undertightening fails to compress the seal adequately, causing leaks. Using damaged fittings or exposing them to incompatible fluids are other common failure points.

For the durability and precision your equipment demands, trust genuine Wayfong components. Our Metric Hydraulic Hose Fittings are built to the highest specifications to ensure your system's integrity. Contact us today to speak with our technical experts, request a detailed catalog, or find your local Wayfong distributor for all your hydraulic connection needs.