How to Choose Hexagon Lock Nuts for Industrial Applications?

2026-01-04

Abstract: Hexagon Lock Nuts are a critical component in industrial fastening systems. This comprehensive guide explores their specifications, applications, common questions, and selection criteria to ensure optimal performance in mechanical and structural installations.

Table of Contents

- 1. Introduction to Hexagon Lock Nuts

- 2. Specifications and Parameters

- 3. Industrial Applications and Use Cases

- 4. Common Questions About Hexagon Lock Nuts

- 5. Conclusion and Brand Insight

1. Introduction to Hexagon Lock Nuts

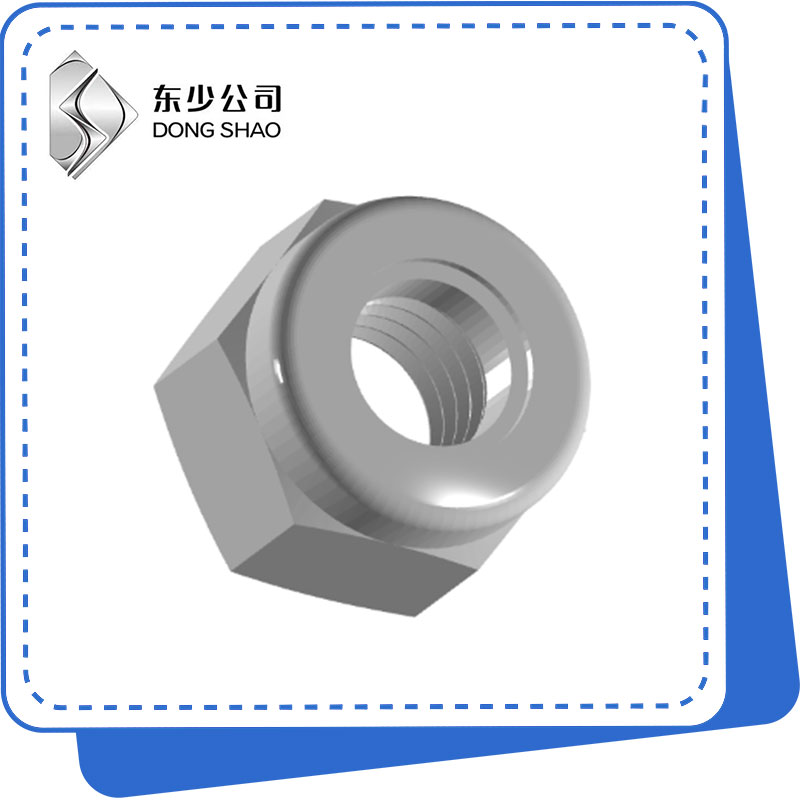

Hexagon Lock Nuts are specialized fasteners designed to provide secure connections in mechanical and structural assemblies. Unlike standard nuts, they feature anti-loosening properties, ensuring stability under vibration, torque, and dynamic loads. The primary focus of this article is to guide engineers, procurement specialists, and industrial users in understanding the key aspects of Hexagon Lock Nuts, including specifications, applications, and troubleshooting tips for optimal selection.

Hexagon Lock Nuts are widely used in automotive, construction, heavy machinery, and precision equipment due to their reliability and durability. Understanding their technical parameters and performance characteristics is essential for achieving safety and efficiency in engineering projects.

2. Specifications and Parameters

The following table summarizes the primary specifications of Hexagon Lock Nuts available from industry-standard suppliers. These parameters assist in selecting the appropriate nut for specific applications:

| Parameter | Specification |

|---|---|

| Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Thread Size | M3 to M36 (Metric), 1/4" to 1-1/2" (Imperial) |

| Coating/Finish | Zn Plated, Black Oxide, Nickel Plated, Plain |

| Strength Grade | 8, 10, 12 (Metric), Grade 2, 5, 8 (Imperial) |

| Dimensions | Hex Width Across Flats: 5–55 mm; Height: 2.5–30 mm |

| Temperature Range | -40°C to +200°C |

| Application Environment | Vibration-Prone, High Load, Corrosive Conditions |

These parameters are crucial for engineers to evaluate compatibility with bolts, torque requirements, and environmental conditions.

3. Industrial Applications and Use Cases

Hexagon Lock Nuts are widely adopted across multiple industries. Their anti-loosening mechanism ensures structural integrity under dynamic loads. Below are key industrial applications:

3.1 Automotive and Transportation

Used in engine assemblies, chassis mounting, suspension systems, and braking systems where vibration is constant and safety is paramount.

3.2 Construction and Heavy Machinery

Integral in securing structural steel frameworks, cranes, conveyor systems, and earth-moving equipment to maintain reliability under heavy loads.

3.3 Industrial Equipment and Electronics

Applied in assembling high-precision machinery, pumps, compressors, and electronic enclosures to prevent loosening caused by operational vibration.

3.4 Marine and Corrosive Environments

Stainless steel Hexagon Lock Nuts with corrosion-resistant coatings are used for ships, offshore platforms, and chemical plants to resist seawater and chemical exposure.

4. Common Questions About Hexagon Lock Nuts

Q1: How to determine the correct Hexagon Lock Nut size for a specific bolt?

A1: The size of the Hexagon Lock Nut should match the bolt thread diameter and pitch. For metric bolts, use the standard M-series sizing (e.g., M8, M12). For imperial bolts, match the nominal diameter (e.g., 1/2", 3/4") and thread count (TPI). Ensuring proper fit prevents thread stripping and maintains fastening integrity.

Q2: What materials are best for Hexagon Lock Nuts in high-stress environments?

A2: For high-stress or load-bearing applications, alloy steel or high-grade carbon steel nuts with hardened surfaces are recommended. Stainless steel is ideal for corrosive environments but may have lower strength. Selecting the right material depends on mechanical load, temperature range, and environmental conditions.

Q3: Can Hexagon Lock Nuts be reused after removal?

A3: Reusability depends on the type and locking mechanism. Nylon-insert lock nuts can generally be reused a limited number of times without losing effectiveness. All-metal lock nuts with distorted threads or deformed surfaces are often single-use. Proper inspection is necessary to ensure continued performance.

Q4: How to prevent Hexagon Lock Nuts from loosening in high-vibration applications?

A4: Anti-vibration measures include using nylon-insert lock nuts, applying thread-locking compounds, or using double-nut assemblies. Correct torque application using a calibrated torque wrench is critical to maintain clamping force without over-tightening.

Q5: Are there specific standards for Hexagon Lock Nuts?

A5: Yes, Hexagon Lock Nuts are manufactured according to standards such as ISO 7040, DIN 985, ANSI/ASME B18.16.6, and BS 3692. These standards define dimensions, material grades, mechanical strength, and tolerances to ensure interchangeability and reliability across industrial applications.

5. Conclusion and Brand Insight

Hexagon Lock Nuts remain an indispensable component in modern engineering and industrial projects. Selecting the appropriate size, material, and type is critical to achieving mechanical reliability and safety. DONGSHAO provides a wide range of high-quality Hexagon Lock Nuts, engineered for durability and performance in diverse industrial environments. For personalized guidance and bulk supply inquiries, contact us today to explore the best solutions for your fastening requirements.