How Much Load Can a Wind Power Flange Typically Withstand

2025-12-17

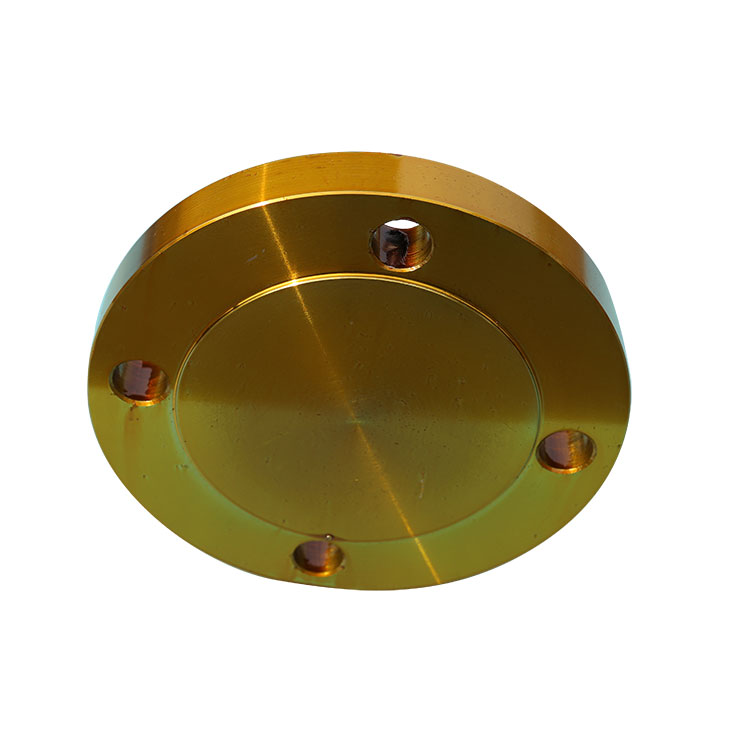

At the heart of every reliable wind turbine lies a critical connection point: the Wind Power Flange. This component bears immense responsibility, transferring colossal loads from the massive tower and blades down to the foundation. Understanding its load-bearing capacity is not just technical jargon—it's fundamental to ensuring decades of safe, efficient energy production. As a leading force in this precision-driven industry, Jiangyin Huaxi Flange Pipe Fittings Co., Ltd specializes in engineering flanges that meet and exceed the extreme demands of modern wind energy.

The specific load a flange can withstand is not a single number but a complex interplay of design, material, and manufacturing quality. Key factors include:

-

Material Grade: High-strength, low-alloy steels are essential.

-

Flange Type & Dimensions: Such as tower, blade, or nacelle flanges.

-

Load Types: Including axial force, bending moment, shear force, and fatigue cycles.

-

International Standards: Compliance with DIN, EN, ASTM, or GL certifications.

At Jiangyin Huaxi, our Wind Power Flanges are built to endure. We utilize forged S355NL/QL and ASTM A707 L5 steels, renowned for their excellent mechanical properties and impact resistance at low temperatures. Our production process ensures superior internal density and structural integrity.

For a clearer overview, here are typical performance parameters for our standard tower flanges:

| Parameter | Specification | Standard / Note |

|---|---|---|

| Material Grades | S355NL, S355ML, ASTM A707 L5 | EN 10222 / ASTM A707 |

| Yield Strength (Min) | 355 MPa | Ensures structural stability |

| Tensile Strength | 470 - 630 MPa | High load-bearing capacity |

| Impact Toughness | ≥ 40 J @ -20°C / -40°C | Key for low-temperature sites |

| Max. Outer Diameter | Up to 5000 mm | For multi-MW turbine applications |

| Flange Ring Flatness | ≤ 0.5 mm | Guarantees perfect mating surface |

Wind Power Flange FAQ

Q: What are the most critical quality tests for a Wind Power Flange?

A: Beyond standard dimensional checks, non-destructive testing (NDT) is paramount. Every Jiangyin Huaxi flange undergoes rigorous ultrasonic testing (UT) to detect internal flaws and magnetic particle inspection (MT) for surface defects. Additionally, mechanical property tests and Charpy V-notch impact tests are mandatory to validate performance against specifications.

Q: How does manufacturing method affect a flange's load capacity?

A: Significantly. Forged flanges offer a continuous grain flow and superior strength compared to cast or cut-from-plate alternatives. Jiangyin Huaxi employs precision die forging, which enhances the metal's fatigue life and overall load-bearing capability, making our flanges ideal for withstanding dynamic wind loads over 20+ years.

Q: Can you provide custom Wind Power Flanges for specific project requirements?

A: Absolutely. While we stock standard sizes, custom engineering is a core competency. We can adjust dimensions, material grades, bolt hole patterns, and special coatings (like hot-dip galvanizing) to meet unique load profiles, site conditions, or turbine manufacturer specifications.

The load a Wind Power Flange can withstand defines the turbine's resilience. Don't compromise on this vital link. Partner with a manufacturer that combines proven metallurgical expertise with precision craftsmanship.

Contact us today at Jiangyin Huaxi Flange Pipe Fittings Co., Ltd. Let our engineering team provide detailed technical data sheets and collaborate with you to specify the perfect flange for your wind power project's load demands.