How Does a Flat Flange Differ from a Raised Face Flange

2026-01-05

In the world of industrial piping and fluid systems, selecting the correct flange type is critical for safety, integrity, and performance. Two of the most common yet distinct designs are the Flat Flange and the Raised Face Flange. Understanding their differences is key to specifying the right component for your application. At Longan, we specialize in providing high-quality, precision-engineered flanges, and we’re here to clarify these fundamental designs to help you make an informed decision.

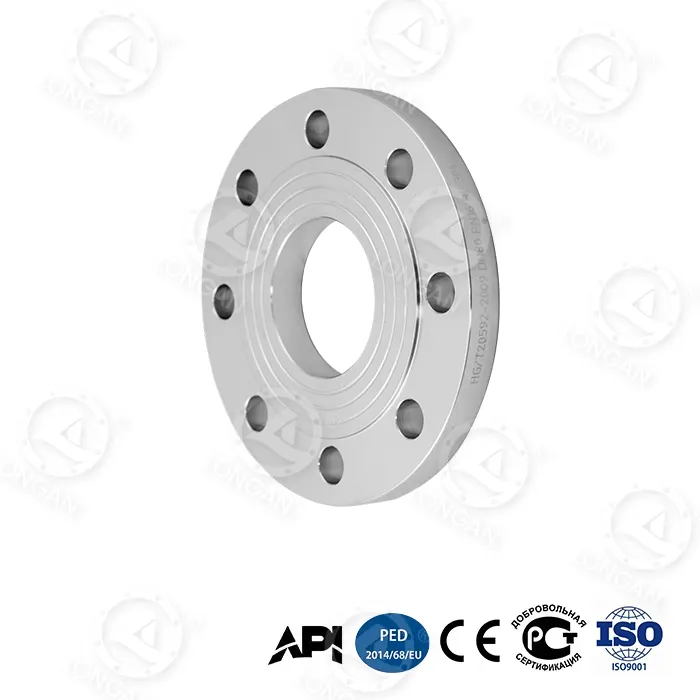

The core distinction lies in the gasket sealing surface. A Flat Flange, also known as a plain face flange, has a sealing surface that is completely flat and level across its entire face. This design is typically used with full-face gaskets that cover all the bolt holes. In contrast, a Raised Face Flange features a small, raised ring (usually 1/16" for 150# and 300# ratings, or 1/4" for higher classes) around the bore. This raised section is the contact surface for the gasket, which is normally a ring-type gasket that fits inside the bolt circle.

Key Differences at a Glance:

-

Gasket Type: Flat Flanges use full-face gaskets; Raised Face Flanges use ring gaskets.

-

Contact Pressure: The raised face concentrates bolt load on a smaller area, often allowing for a higher sealing pressure with less torque.

-

Common Applications: Flat Flanges are common for low-pressure applications, cast iron equipment, and connections where the mating flange is also flat. Raised Face Flanges are the industry standard for most steel piping systems handling moderate to high pressures and temperatures.

To further illustrate, here is a comparative breakdown:

| Feature | Flat Flange (FF) | Raised Face Flange (RF) |

|---|---|---|

| Sealing Surface | Entire face is flat | Raised ring around the bore |

| Gasket Type | Full-face gasket | Ring gasket |

| Typical Material | Often Cast Iron, Ductile Iron | Typically Carbon Steel, Stainless Steel |

| Pressure Rating | Lower (e.g., Class 125, 250) | Higher (Class 150 through 2500+) |

| Best For | Low-pressure systems, valve bodies, pump casings | Most common industrial piping systems |

Flat Flange FAQ

Q: Can a Flat Flange be bolted to a Raised Face Flange?

A: This is not recommended. The mismatch in sealing surfaces will result in improper gasket compression and a high probability of leakage. Mating flanges should always have identical facing types.

Q: When should I specifically choose a Longan Flat Flange?

A: Choose a Longan Flat Flange when connecting to equipment with flat-faced openings (like many pumps and valves), for low-pressure utility services, or when using materials like cast iron where the flat face is standard. Our flanges are machined to exact tolerances for a perfect seal.

Q: Are Flat Flanges less expensive than Raised Face Flanges?

A: Often, yes. The simpler machining and common use with lower-cost materials like cast iron can make Flat Flanges more economical for suitable applications. However, the total installed cost depends on the gasket and specific service requirements.

Selecting the right flange facing is a fundamental step in ensuring a leak-free and safe piping system. While the Raised Face Flange dominates general industrial use, the Flat Flange remains the essential choice for specific equipment and pressure conditions. For expert guidance and a reliable supply of both Flat Flange and Raised Face Flanges manufactured to the highest standards, look no further than Longan. Our team is ready to assist you in selecting the optimal component for your project’s pressure, temperature, and media.

Contact us today for a quote or to discuss your specific flange requirements with our engineering support team.