How Do You Calculate the Load Capacity of a Thrust Ball Bearing

2026-01-06

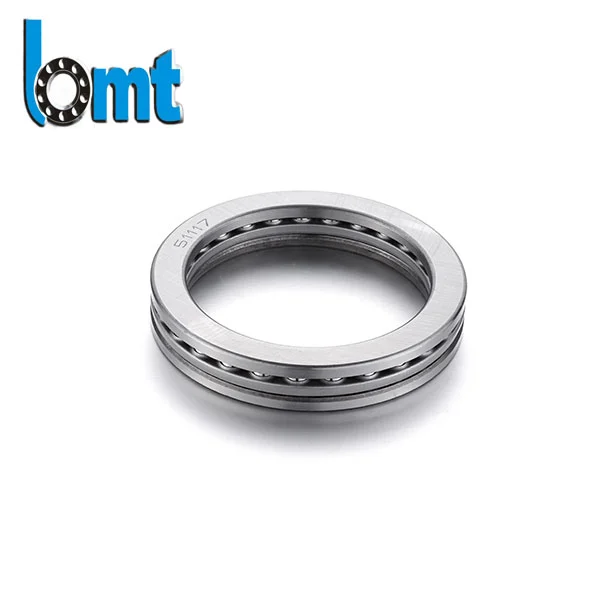

Selecting the correct bearing is fundamental to any mechanical design. When your application involves managing primarily axial loads, Thrust Ball Bearings are a critical component. At BMT, we understand that precise engineering starts with accurate calculations. Incorrect load capacity estimation can lead to premature failure, downtime, and increased costs. This blog provides a professional guide to calculating the load capacity of a Thrust Ball Bearing, ensuring your designs are robust and reliable.

The load capacity of a bearing defines the maximum load it can endure while maintaining specified performance over its expected life. For Thrust Ball Bearings, this revolves around the basic dynamic axial load rating (C₀) and the basic static axial load rating (C₀ᵣ). Here’s how to approach the calculation:

1. Identify Key Parameters:

-

Basic Dynamic Axial Load Rating (C₀): Provided in the bearing manufacturer's catalog (e.g., BMT's technical datasheets). This is the constant axial load a bearing can withstand for 1 million revolutions.

-

Basic Static Axial Load Rating (C₀ᵣ): Also from the catalog. This is the maximum static axial load the bearing can handle without permanent deformation.

-

Equivalent Dynamic Axial Load (Pₐ): The calculated load that considers both pure axial load and any induced effects.

-

Required Life (L₁₀): The desired operating life in millions of revolutions.

2. Perform the Core Calculations:

-

For Dynamic Load Capacity (Life Calculation): The standard life equation is:

L₁₀ = (C₀ / Pₐ)³

Rearranged to find the required dynamic load rating:

C₀ required = Pₐ * (L₁₀)^(1/3) -

For Static Load Capacity Check: Ensure the applied static axial load (Fₐ₀) is less than the static load rating, applying a safety factor (s₀):

C₀ᵣ ≥ s₀ * Fₐ₀

3. Consider Application Factors: Actual calculations must incorporate service factors for speed, temperature, and vibration, which adjust the equivalent load Pₐ.

For quick reference, here is a simplified factor table for common conditions:

| Application Condition | Typical Service Factor (fₐ) |

|---|---|

| Steady Load, Low Vibration | 1.0 - 1.2 |

| Moderate Shock Load | 1.2 - 1.5 |

| Heavy Shock Load, High Vibration | 1.5 - 3.0 |

Thrust Ball Bearings FAQ

Q: Can a thrust ball bearing handle radial loads?

A: No, standard thrust ball bearings are designed exclusively for axial loads. Applying significant radial load will cause excessive wear and rapid failure. For combined loads, consider angular contact ball bearings or tapered roller bearings from the BMT portfolio.

Q: What is the main difference between static and dynamic load ratings?

A: The static load rating (C₀ᵣ) concerns load while stationary or at very low speeds, preventing permanent deformation. The dynamic load rating (C₀) relates to load under rotation, determining the fatigue life (L₁₀ life) of the bearing.

Q: How does lubrication affect the load capacity?

A: Proper lubrication is critical. It forms a protective film separating rolling elements from raceways, reducing friction and wear. Inadequate lubrication drastically reduces effective load capacity and service life. BMT provides specific lubrication recommendations for each bearing type.

Accurately calculating load capacity is not just a formulaic exercise; it's the foundation of reliability and efficiency in your machinery. While this guide provides the core principles, real-world applications involve nuances that demand expert attention.

Have a specific application challenge or need verification of your calculations? Our engineering team at BMT is ready to assist. We provide not only premium Thrust Ball Bearings but also the technical expertise to ensure they perform flawlessly in your system. Contact us today for personalized support and access to our comprehensive technical catalogs.