How Do Plain Washers Improve Safety in Mechanical Fastening

2025-12-16

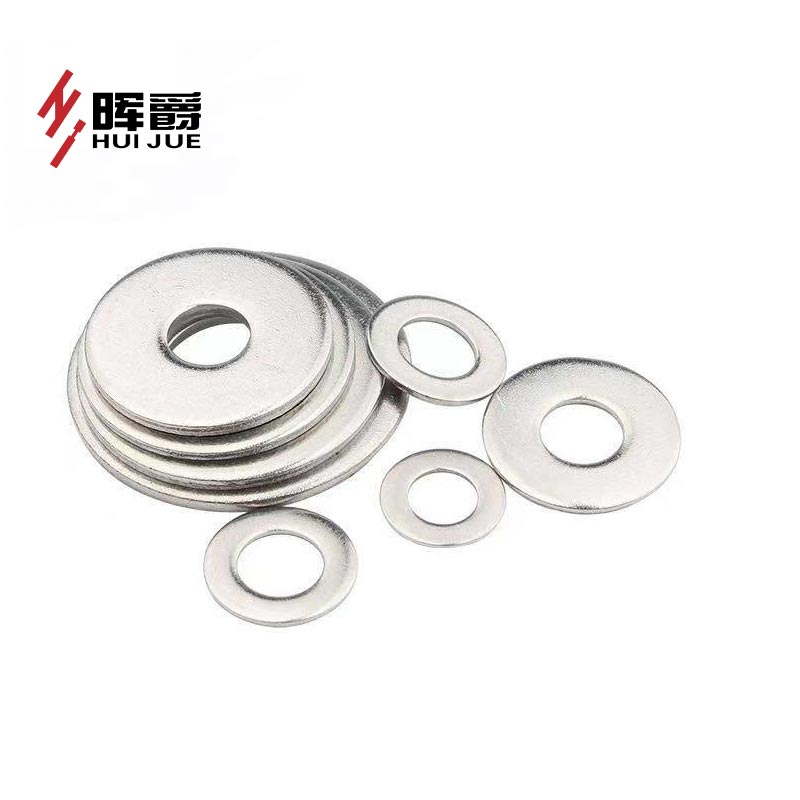

In the world of mechanical assembly, safety and reliability are paramount. Often overlooked, the humble Plain Washer is a critical component in ensuring the integrity of bolted joints. At Huijue, we engineer these essential components to be the unsung heroes of secure fastening. Their primary role in enhancing safety is multifaceted, preventing catastrophic failures that can lead to equipment damage, operational downtime, or personal injury. By distributing load, protecting surfaces, and ensuring proper clamp force, Plain Washers directly contribute to the longevity and safety of countless applications.

The safety benefits provided by Huijue Plain Washers are rooted in precise engineering and material science. Here’s how they work:

-

Load Distribution: They spread the compressive force of the nut or bolt head over a larger area.

-

Surface Protection: They prevent damage to soft or finished surfaces from rotational friction during tightening.

-

Vibration Resistance: By maintaining consistent clamp force, they help joints resist loosening under vibration.

To meet diverse industrial demands, Huijue manufactures a comprehensive range of Plain Washers with exacting specifications.

| Parameter | Details & Huijue Specifications |

|---|---|

| Materials | Carbon Steel (Grade 4.8, 8.8), Stainless Steel (A2-304, A4-316), Brass, Aluminum. |

| Standards | Compliant with DIN, ANSI/ASME, ISO, and JIS standards for global interoperability. |

| Finishes | Zinc Plated, Hot-Dip Galvanized, Black Oxide, and Natural Passivation for corrosion resistance. |

| Sizing | Precise inner/outer diameters and thicknesses, meticulously graded for M3 to M30+ and #4 to 1”+ fastener systems. |

Plain Washers FAQ

Q: When is it absolutely necessary to use a plain washer?

A: It is crucial when fastening onto soft materials (like aluminum or plastic) to prevent embedding, when the bolt hole is oversized or slotted, or when the contact surface is uneven. Huijue washers ensure the load is properly transferred in these high-risk scenarios.

Q: Can I reuse plain washers?

A: It is generally not recommended, especially in critical or high-torque applications. Huijue washers are designed to deform minutely to seal the joint. Reuse compromises this seal and load-bearing capacity, potentially compromising safety.

Q: How do I select the correct material for my plain washer?

A: The choice depends on the application environment. For general use, Huijue carbon steel washers are economical. For moisture or chemical exposure, our A4-316 stainless steel is ideal. For electrical or marine applications, our brass or aluminum washers prevent galvanic corrosion.

In conclusion, the safety embedded within a mechanical assembly often relies on the fundamental performance of Plain Washers. Choosing a trusted manufacturer like Huijue means selecting components built with precision, consistency, and a deep understanding of mechanical integrity. Don't let the smallest part be the weakest link in your design.

Contact us today to request a catalog, get a quote for your specific project needs, or consult with our engineering support team on selecting the optimal Huijue Plain Washers for your safety-critical applications.