How Are Self-drilling Screws Used and Installed Effectively?

2025-12-25

Article Summary

This article explores the technical aspects, applications, installation methods, and common challenges of Self-drilling Screws. It includes detailed product specifications, answers common user questions, and provides insights into achieving maximum efficiency and durability in construction and industrial projects. The guide also highlights the DONGSHAO brand and provides contact information for inquiries.

Table of Contents

Introduction to Self-drilling Screws

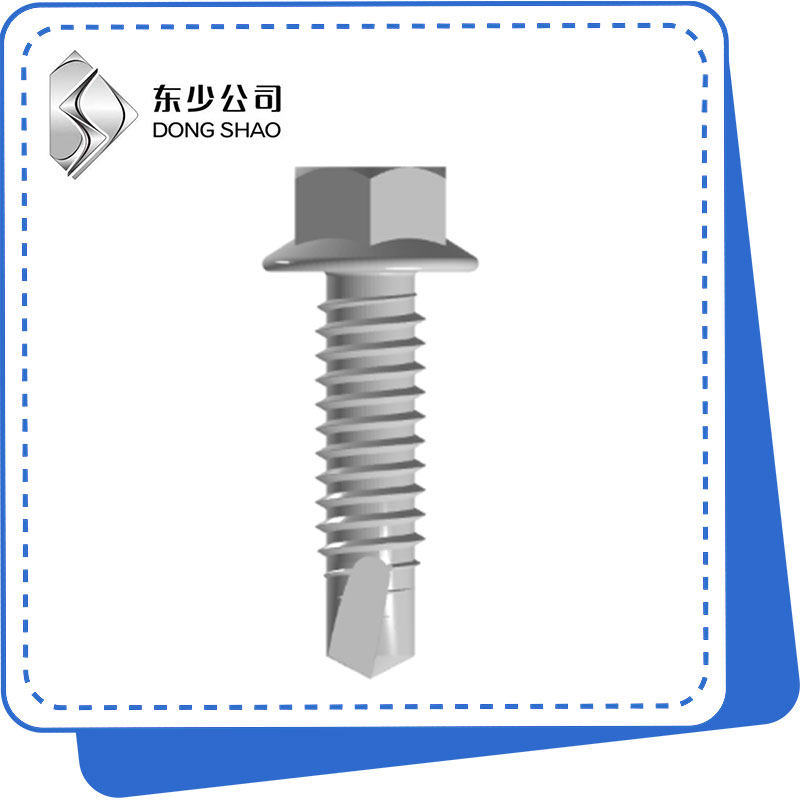

Self-drilling screws are specialized fasteners designed to drill their own hole and secure materials without the need for pre-drilling. These screws are widely used in metal construction, automotive assembly, and industrial manufacturing due to their efficiency and reliability. This article provides a complete guide on the selection, application, and installation of Self-drilling Screws, aiming to answer the most critical questions professionals encounter in daily operations.

Technical Specifications and Parameters

Understanding the technical parameters of Self-drilling Screws is essential to ensure compatibility with different materials and mechanical requirements. Below is a detailed summary of commonly used specifications:

| Parameter | Description |

|---|---|

| Material | High carbon steel, stainless steel, or zinc-plated steel depending on corrosion resistance requirements. |

| Thread Type | Full thread, partial thread, coarse or fine pitch designed for metal, wood, or composite materials. |

| Point Type | Drill point (TEK-style), self-tapping point, or wafer point for different thicknesses. |

| Diameter Range | M3 to M12 for standard applications, with custom sizes available upon request. |

| Length Range | 10mm to 200mm depending on structural requirements. |

| Head Type | Hex, pan, countersunk, or wafer head compatible with various driving tools. |

| Coating | Galvanized, zinc, or black oxide for corrosion resistance and improved durability. |

| Torque Specifications | Recommended torque ranges based on diameter and material hardness to avoid thread stripping or material damage. |

Usage and Installation Techniques

How to Select the Right Self-drilling Screw for Metal Construction?

When selecting a Self-drilling Screw for metal structures, it is critical to consider material thickness, hardness, and corrosion requirements. Screws with TEK-style drill points are ideal for thin-gauge metals, while high-strength screws are necessary for thicker steel or alloy components.

How to Ensure Proper Drilling and Fastening?

Proper torque and driving speed are crucial. Excessive torque can strip threads, while insufficient torque may cause weak fastening. Use electric screwdrivers or drills with adjustable clutch settings. Ensure the screw tip aligns perpendicularly to the surface for clean penetration.

How to Avoid Common Installation Errors?

Common mistakes include pre-drilling unnecessarily, using incorrect drill points, or selecting the wrong screw length. Always match screw length to combined material thickness and avoid overlapping structural components that exceed the screw's drilling capacity.

How to Maintain Longevity of Installed Screws?

Corrosion protection is critical. For outdoor or high-moisture environments, select screws with galvanization or stainless steel. Inspect periodically for loosening or corrosion, especially in high-vibration applications such as machinery or automotive components.

Common Questions About Self-drilling Screws

Q1: Can Self-drilling Screws be used on stainless steel?

A1: Yes, but it is recommended to use screws with a high hardness rating and specialized drill points. Stainless steel is more resistant to drilling, so slower driving speed and higher torque are needed.

Q2: What is the maximum thickness a Self-drilling Screw can penetrate?

A2: The maximum thickness depends on the screw type and material. Standard TEK screws can penetrate up to 12mm of mild steel, while heavy-duty variants can go up to 25mm. Always refer to manufacturer specifications for exact limits.

Q3: How to prevent stripping threads during installation?

A3: Use the correct torque and driving method. Over-torquing or using worn driver bits increases the risk of stripping. Pre-check alignment and consider pilot holes for extremely hard materials.

Q4: Can Self-drilling Screws be removed and reused?

A4: They can be removed, but reusing screws may reduce holding strength due to thread deformation. For critical applications, using new screws is recommended.

Conclusion and Contact

DONGSHAO provides a comprehensive range of Self-drilling Screws designed to meet various industrial, construction, and mechanical applications. By understanding specifications, installation methods, and best practices, professionals can maximize efficiency, safety, and longevity of their projects. For inquiries or to explore customized solutions, contact DONGSHAO directly through their customer service channels.

Contact Us for detailed product information and professional guidance.