Home > Products > Combination & Joint Fittings > Stainless Steel Food Grade Tube Clamp ( JN -FL2007)

Stainless Steel Food Grade Tube Clamp ( JN -FL2007)

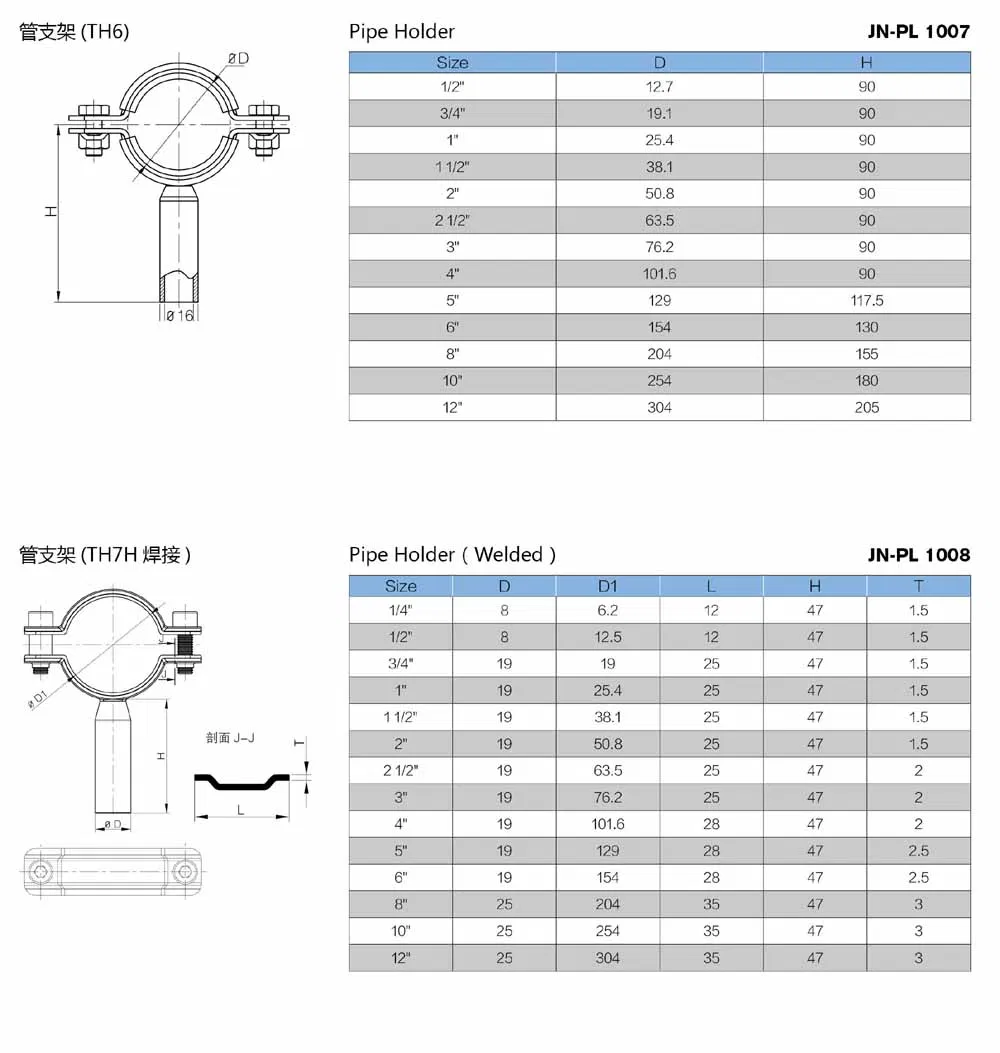

Non-contacting partStandard: DIN, SMS, ISO, 3A, BPE, IDF, AS, BSSize: DN10-300, 1/2"-10"Material: SS304, SS201, SS316L for some special applicationsGasket: EPDM, SILICONE, PFTE, NBRApplication: Food, beverage, dairy, pharmacy, chemical or any food processing industries ABOUT OUR COMPANY ......

Send Inquiry

Product Description

Non-contacting part

Standard: DIN, SMS, ISO, 3A, BPE, IDF, AS, BS

Size: DN10-300, 1/2"-10"

Material: SS304, SS201,

SS316L for some special applications

Gasket: EPDM, SILICONE, PFTE, NBR

Application: Food, beverage, dairy, pharmacy, chemical or any food processing industries

ABOUT OUR COMPANY

| JoNeng valves company was started in 2007. Located in the stainless steel industry zone, Wenzhou, China. |

| Totally 130nos of workers and the factory Covers 5000m2. Till now, we have 34 sets of LG Mazak machines and other local CNC machines; Plus, we have 2 sets of automatic machining unit. To assure better quality, we have the full inspecting quality control equipment: 1nos Ra roughness instrument, 3nos stainless steel spectrometer, numbers of roundness instrument, numbers of thickness instrument, numbers of radius instrument, 3 nos pressure testing center. |

| JoNeng valves provides the following sanitary flow control components: Stainless steel sanitary valve ( stainless steel sanitary butterfly valve, sanitary diaphragm valve, sanitary check valve, sanitary ball valve, sanitary CPM valve, ...) stainless steel sanitary pipe fittings( stainless steel sanitary elbow, tee, clamp, ferrule, union, cleaning ball, sight glass, filter...) Stainless steel Sanitary pump ( stainless steel sanitary centrifugal pump, rotary lobe pump, CIP pump) |

| JoNeng services for food, beverage, dairy, chemical, bioth, pharmaceutical, and etc industries. |

| JoNeng customers are from 55 different countries.After so many years, JoNeng know more about different requirements from different countries' customers. JoNeng valves believes in "What we say, what we do". We always believe honesty and responsibility is the only way leading to long term business relationship. Trying our best for customers and put ourselves into customers' shoes. Our commitment " Never let customers leave us because our poor quality". Making business with us, making friends with us. |

OUR PRODUCTION CAPACITY

| Production Lines | Stainless steel sanitary pipe fittings' line, machining line, sanitary manhole line, | |

| Product Range | sanitary butterfly Valve, sanitary diaphragm valve, sanitary pipe fittings, union, ferrule, sight glass, manhole cover, safety valve, sampling valve.... | |

| Year Established | 2007 | |

| Factory Size in Square Meters | 5000M2 | |

| NO. OF TOTAL STAFF | 130 | |

| Production Capital | 8 000 000 USD | |

| Detail capacity | Manhole covers | 12000nos |

| Pipe fittings | 150000nos | |

| Ferrules, unions, connectors | 200000nos | |

| Diaphragm valves | 15000nos | |

| Butterfly valves | 20000nos | |

| Investment in Manufacturing Equipment | 750000usd | |

| Details of equipment | For machining parts 29 nos of LG Mazak CNC Machines 4 nos of local CNC machines 2 nos of automatic CNC center 12 nos of plain lathe For pipe fittings 4 nos of press 3 nos of cutting machine 3 nos of chamfering machine We also have the following quipments 4 nos of polishing machine 12 nos of grinding machine 3 nos of laser marking machine 3 nos of pressure testing machine 1 nos of temperature testing machine 3 nos of spectro instrument 1 nos of surface roughness device | |

| Primary Competitive Advantages | Strict inspection , honest business way, fast revert on order problem | |

| Stocked materials | Big quantity for raw forging of butterfly valve, diaphragm valve, ferrule, union, adapters, pipe fittings, clamps, sight glass, safety valve, manhole cover, | |

| OEM Services Provided | yes | |

| Design Service Offered | yes | |

| Sales Volume | 6 000 000 usd | |

| Export Percentage | 80% | |

| MAIN MARKET | USA, Germany, Hungary, Canada, Thailand, Holland, England, South Africa,Indonesia, Saudi, India, New Zealand, Australia, Middle East... | |

| Own Brand Name | JoNeng | |

OUR STOCK

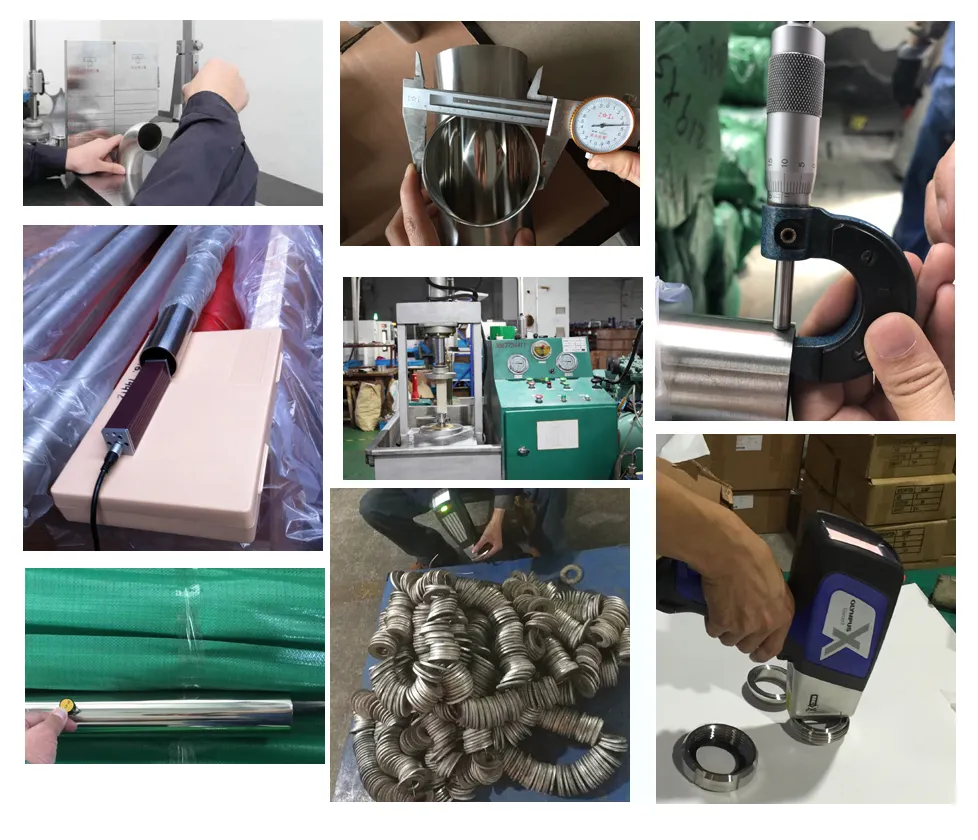

OUR INSPECTION

| HOW DO WE MAKE THE QUALITY CONTROL | |

| For Raw Materials | 1. Material control from raw materials. For raw material checking, we check 100% by chemical liquid. Any property mistakes would be rejected. 2. Sand hole inspection after raw materials are machining before polishing. 3. Carbon component report can be provided if needed 4. Mechanics test report can be provided if needed |

| For New products | 5. 2nos of new samples to be checked against technical drawing. Testing report is provided to customers before bulk production. |

For finished materials | 6. For valves, pressure testing and temperature testing is required for each valve. 7. After we get the finished products, we check for surface roughness, thickness equality, roundness, size measurement and sand holes again. 8. For all finished products, the checking quantity is not less than 10% of total quantity. 9. Before shipment, we check for the quantity of each product in order to find out any missing quantity or wrong product. |

OUR EXHIBITION

FAQ:

FAQ:1. Are you a trading company or factory? We are a manufacturing factory.

2. Do you have FDA certificate for the materials? Yes, FDA is very important for the food processing machines.

3. How do you control the quality?

Quality control is very important to avoid material mixing and poor quality. We control the quality from beginning to the end. We only have 304 and 316L two different materials. 100% inspection on raw materials. During production, different materials in different places. After materials are finished, we choose 10% for inspection. If there is 0.1% problem in 10%, then no excuse to go ahead for inspecting 100% of the materials.

4. About chemical components

This is first concerning for customers. We take our materials to our laboratory for each lot. You may ask for the laboratory report any time.

5. If there is any quality problem, how do you solve it?

We are very proud that we never let one customer leave us. We are not 100% perfect, there is some quality problem. We try our best to provide the correct materials in the beginning, so we need less time for quality problem.

If there is any quality problem, we take the responsibility. We believe what we are doing together, it will get back tomorrow. If we leave our responsibility, customers will leave us. If we always take our responsibility, we keep our customers with us.

6. How long is your delivery time? For normal products in 7-10 days; for bulk order, in 15-25 days. It depends.

7. Warranty

3 years warranty for all of our stainless steel products. Gaskets are not included due to the different application for customers.

8. More questions are appreciated.

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.